Breathing Air Compliance Test...Attended site as arranged and completed work in a tidy efficient manner causing minimum disruption to site operations. Recommendation from a customer in Bedfordshire. For more informat...

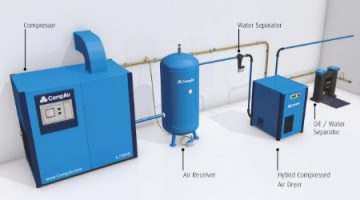

We have been helping customers with compressed air pipework and design over many years. We help them develop and install their compressed air pipework systems. We are installing pipework for customers on a daily basis across the South East of England, Midlands and East Anglia and beyond.

Our aim is always to provide our customers with the most appropriate and best pipework solution for their particular circumstances. We will normally meet the customer on site and discuss their requirements, understand what they want and any existing system they may have. We will then propose the most appropriate routing, pipework system and how we will integrate it into their current system.

Normally we work with one of 3 different types of compressed air pipework, although we do use other systems if required.

All three systems offer benefits depending on the exact customer application and existing legacy system.

Teseo is a square profile, smooth bore aluminum system. Extruded aluminium has significant advantages over traditional galvanised steel pipework.

Light weight – making it easier to install requiring less sturdy fixings

Reduced pressure drops – the smooth bore makes pressure drop through the pipe significantly lower than traditional pipework

Easily modified – Pipework systems tend to grow and change over time. Teseo is easy and quick to modify requiring less downtime. In fact it is possible to add drops to a live circuit in certain circumstances

High pressure – suitable for up to 25 bar

Teseo is available in a number of different sizes to allow for different flow rates and demand patterns. Joints are made and sealed with connectors all of which have double O rings for security. The connectors are held together with clamps Teseo is a unique product on the market.

Find out more here

Transair is a round smooth bore aluminium system. Available in blue or silver finish. Joints are made of high strength plastic and simply require a push fit to seal. Available in a number of different sizes to manage different flow rates and demand patterns. Transair offers many of the same benefits as Teseo above but there are a number of very similar products on the market which aren’t necessarily compatible.

The original compressed air pipework and still a legacy system in many companies around the region. Works well when installed and maintained correctly but tends to leak after a few years when the joints begin to corrode.

Having the latest smooth bore pipework is a good start point for an efficient and effective pipework system. But of equal importance is having a system that is designed and maintained properly.

‘The more air you want to use the bigger the pipe needs to be’

This sounds obvious but we commonly find huge amounts of air trying to get through very small ‘pinch points’ in a pipework system. A good rule of thumb is…

Note: if you have multiple compressors the pipework needs to be based on the total capacity of all the compressors combined.

We also try to always fit bigger pipework in the plant room particularly if you have multiple compressors.

Breathing Air Compliance Test...Attended site as arranged and completed work in a tidy efficient manner causing minimum disruption to site operations. Recommendation from a customer in Bedfordshire. For more informat...

Compressed air pipework – specification, design and install

Professional support when you need it

Air Equipment can support you and your compressed air system throughout its life. We will monitor your system to ensure it remains reliable, efficient and operating correctly. We will service your compressors, filters and air dryers to schedule, to ensure they continue to operate correctly. We can also help and guide you through changes to your air system as your company changes and grows.

Learn about usSign up to the free newsletter and receive our monthly bulletin.