No hesitation to recommend them..."A very reliable company, with a great level of customer service. I would have no hesitation about recommending them to other users." Annual service of compressor...

There has been a rapid change in the technology within the compressed air industry over the past 10+ years. These changes have helped improve air compressor energy efficiency and controllability, and more broadly compressed air systems considerably.

However, frequently there are a number of basic basic things that can be done to greatly improve system efficiency without the need to spend money on new plant.

Click here to see more information about how to save energy from your compressed air system

Saving energy on your compressed air system means that you may need to look at many parts of the system. There isnt just one way to ‘fix’ the system. Areas that need to be considered typically include compressor and dryer type, pipework sizing and route, receiver size, leaks, operating pressure of the system and many more.

Areas to focus on for maximum benefit are relatively easy to identify from the Air Equipment Energy Efficiency Audit that we can carry out for you free of charge during a site visit.

Traditionally air compressors are fixed speed so they run at a fixed and consistant speed, which produces a fixed amount of compressed air per minute. This is great if you are using this exact amount of compressed air since the air compressor is constantly running at its most efficient point.

However, as we all know, this is never the case in the real world. The air compressor tends to run to fill up the receiver tank and to supply enough air for the current usage, it then stops running as the required compressed air is drawn off the receiver tank. A few minutes, to a few tens of minutes, later the air has been drawn off the receiver to the point that the compressor has to start up again to pump the system back up to working pressure and so it goes on through the day. Compressors dont like to start and stop frequently so manufacturers build in a ‘run on timer’. This means that every time the compressor reaches required pressure rather than simply stopping it ‘runs on’ for about 5 – 10 minutes. In this time the machine is turning, absorbing energy, but not making any air. This leads to the inefficiency of fixed speed compressors, particularly for applications with irregular demand.

Variable speed compressors are an innovation that enables the compressor to rotate more slowly, producing less air, absorbing less energy. The variable speed machine try’s to alter the amount of air it produces to exactly match air demand, saving a considerable amount of energy.

Click here to find out more about variable speed compressors

Having a big powerful air compressor or a number of air compressors producing compressed air is great, but to optimise efficiency of the complete system it is vital to have all this equipment controlled accurately.

If for example you have 3 different sized fixed speed compressors it is always best (most efficient) to use the compressor that is operating nearest to its 100% capacity to supply air to meet current demand. As the working day progresses the air demand changes so the best compressor(s) to use will vary. The current range of air compressor controllers can achieve this quickly and efficiently saving you considerable amounts of energy.

If you add into the mix a variable speed compressor this further complicates the most efficient way to run the system making an electric controller essential to get the best out of the system

Click here to find out more about electronic controllers and datalogging

You may well have highly efficient air compressor, controlled by an advanced electronic controller that switches in the most efficient air compressors throughout the day, so supply always exactly matches demand. If, however, you are then passing this compressed air into an old fashioned, corroded, leaky pipework system all your hard work has been wasted. All your energy saving efforts are literally leaking away.

To find out more about the Air Equipment pipework air leak survey system click here

Similarly we frequently find that compressed air systems have evolved over time so the pipework system as originally designed isnt necessarily being used in the same way today. We often find that large compressors are now being used with pipework that is too small for the flow needed. This results in requiring higher pressures to achieve the required flow or air shortages beyong ‘pinch points’ in the system.

The modern high efficiency aluminium pipework systems are smooth bore, practically leak free if well maintained, corrosion resistant and easy to modify, so you can always have the perfect pipework layout for your system, without resorting to nylon hoses and leaky fittings.

Click here to find out more about our preferred pipework system, TESEO

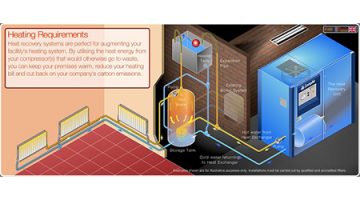

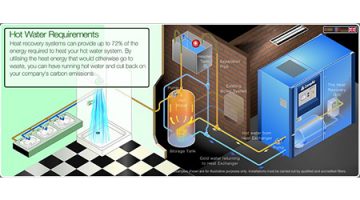

Your air compressor typically uses a large amount of energy to create the compressed air you need to run your factory. The really annoying bit of this is that most of this energy is not actually stored in the compressed air the compressor has made, most of this energy is turned into heat during the compression process. Unfortunately, this fact is a law of nature and that cannot be changed regardless of how efficient the compressor is. This heat is managed within the compressor and is usually discarded to atmosphere as warm air blown through the compressors cooling radiators.

And don’t think this isn’t much energy, in reality, between 80% and 90% of the energy going into a compressor is given off as waste heat. So a 22KW compressor may be discarding between 18 and 20KW of energy as waste heat to atmosphere.

The energy recovery systems that are available with compressors, capture this waste heat and re-use it in various ways. To find out more about the options for energy recovery click here

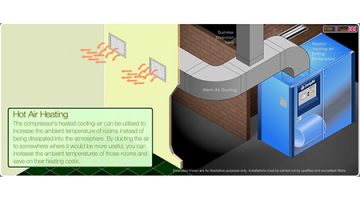

The easiest way to reuse this war air energy is to simply duct the air to somewhere it can be useful. Normally this means ducting the air to a factory or workshop area to act as a space heater. The warm air given off buy the compressor is clean and free from dust or dirt, effectively you get your factory heating for free. Obviously in the summer, when heating is probably the last thing the factory needs the air should be ducted straight to atmosphere, but this is easily achieved with a simple moveable flap in the ductwork.

The other main way of re-using this waste heat is to use it to preheat water, before it goes to a boiler to create hot water. This hot water can then be used for office heating through radiators, or can be used for welfare (such as showers) or for production line processes where hot water is required.

Getting the hot water from the compressor is, again, quite a simple process, only really requiring a small oil / water heat exchanger located in the compressor and water pipework to link the compressor to the hot water feed

No hesitation to recommend them..."A very reliable company, with a great level of customer service. I would have no hesitation about recommending them to other users." Annual service of compressor...

Improving your compressed air system efficiency

Air Compressor maintenance, service and repairs

At the heart of the Air Equipment business is an in depth knowledge of air compressors and compressed air systems. Between us we have hundreds of years experience servicing, repairing and installing compressors. Our depth of experience means that we can rapidly find solutions to customers concerns, minimising the effect of delays and downtimes.

Take a look at our short video about basic daily checks for your compressor

Learn about usSign up to the free newsletter and receive our monthly bulletin.