Project Customer Feedback Received...How Would You Rate the Sales Process & Quotation = 10 How Would You Rate the Installation = 10 How Would you Rate Our Communications with You? = 10<...

Compressor technology has evolved considerably over the past 20 years. Compressors today are more efficient, cleaner and better controlled than ever before. These developments are all designed to help customers save money through energy savings, whilst still providing the necessary compressed air, critical for their production needs.

Industrial screw compressors are broadly split into 4 different types.

Fixed speed lubricated screw compressors

The basic type of screw compressor. Lubricated screw compressors use oil to cool and lubricate the air end, improving efficiency and reducing wear of the compressor. A fixed speed compressor as its name suggests either runs at full speed or is stopped so sizing is critical to maximise efficiency

Variable speed lubricated screw compressors

Lubricated as a fixed speed lubricated compressor but with the advantage of a variable speed motor that controls the speed of the air end to try and match air supply to air demand. This additional control helps save considerable amounts of energy, up to 35% in some applications.

Fixed speed oil free compressors

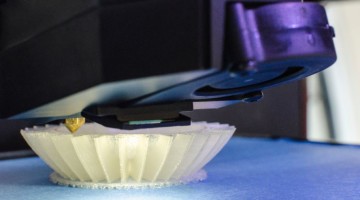

Many food and pharmaceutical applications require compressed air without any trace of lubricating oil. This can be removed with filters, or more reliably, the air can be made in an oil free compressor guaranteeing there is never any oil in the compressed air in the first place.

Removing the lubricating oil from within the air end creates problems for design engineers. How do you remove the massive amount of heat from the compression process and how do you form an effective seal within the air end? Various solutions to these problems have been found ranging from multi stage compressors to water injection.

Note: Fixed speed oil free compressors are comparatively rare particularly at larger sizes since the benefits from variable speed units are so compelling.

Variable speed lubricated screw compressors

All the benefits of the the fixed speed oil free compressor with the additional benefits of energy savings.

Learn more about the different types of industrial air compressor by watching our short video on different compressor types

See our section on how to save energy saving and improve efficiency of your compressed air system here. Or take a look at the Compressor University for more information

At the forefront of these developments is the introduction of variable speed compressors. Variable speed compressors regulate their speed so they produce only the air that is required, rather than switching themselves on and off at regular intervals to meet the required demand.

The main benefit of variable speed compressors is the energy savings they offer compared to a similar sized fixed speed unit. In fact in applications with variable demand (which is practically all of them!) variable speed compressors can save over 30% of the energy used. When you consider that over 80% of the total lifetime cost of a compressor is the energy you put into it a 30% energy saving is huge.

Another major area of development in the compressed air industry is the introduction of oil free compressors. Many industries such as food and pharmaceutical cannot afford for oil contamination of the end products. Oil free compressors, where no oil is used in the compression process, guarantees oil free air. Air Equipment has considerable experience installing servicing and maintaining both oil free and variable speed compressors.

Project Customer Feedback Received...How Would You Rate the Sales Process & Quotation = 10 How Would You Rate the Installation = 10 How Would you Rate Our Communications with You? = 10<...

Fixed speed, variable speed and oil free compressors

Professional support when you need it

Air Equipment can support you and your compressed air system throughout its life. We will monitor your system to ensure it remains reliable, efficient and operating correctly. We will service your compressors, filters and air dryers to schedule, to ensure they continue to operate correctly. We can also help and guide you through changes to your air system as your company changes and grows.

Learn about usSign up to the free newsletter and receive our monthly bulletin.