Excellent Service...

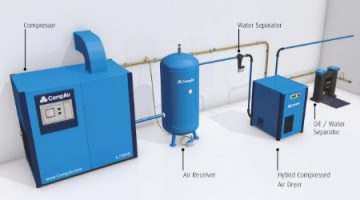

A compressed air system can be responsible for as much as 30% of a factory’s overall energy consumption. Wasting part of this energy through leaking compressed air pipework is simply throwing money away. Analysis your compressed air system is an excellent way to start the optimisation of your plant or manufacturing facility.

One of the simplest and most effective checks to make on your compressed air system is an air leak survey. Unfortunately, traditional galvanised steel compressed air pipework is prone to leaking after only a few years. From surveys, most older pipework systems leak on average 20% – 30% of produced compressed air, so it is clear potential savings are significant.

One of the most common causes of air leaks in older galvanised pipework is corrosion. This normally occurs in the threads at the joints. The corrosion causes the pipe to expand creating an air leak. However there are many other common causes of leaks in compressed air pipework. Faults include; faulty valves, leaks from mechanical damage (such as if a pipe gets knocked by a forklift truck), leaking hoses or nylon tubing, leaking quick release couplings or leaking connections to plant and machinery.

Read more about air leak surveys here

The first and most important step in fixing your air leaks is to identify where the leak is, what is causing the problem and how big the problem is.

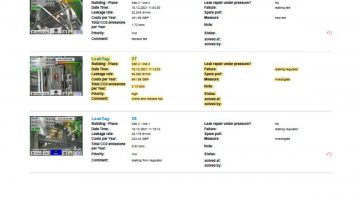

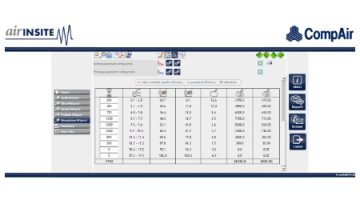

We will typically find 10’s to 100’s of leaks in an older pipework system through an ultrasonic air leak survey. The majority of these will be very small and probably not cost effective to fix. Typically 80% of energy can be saved by fixing 20% of the leaks so these are the ones to focus on. Once we have completed an air leak survey with our highly sensitive ultrasonic tester. We issue a report that lists out each leak we have identified.

The report shows a picture of the area of leak, the size of the leak in l/min and an estimate of the annual cost of the leak based on leak rate, operating hours and cost of electricity.

After discussing the survey results with the customer, the customer can then fix the leaks or we can of course also fix the leaks on their behalf. Typically we will quote to repair the most significant leaks to include the parts required and labour required to repair the leaks.

Modern aluminium pipework is far more leak resistant than older galvanised pipework due to its corrosion resistance, ‘O’ ring seals (giving it better resistance to small movements) and lighter weight. It is also much easier to repair or modify.

There are four simple checks that you can do easily, today, to see how big a problem your factory has with leaking pipework.

1/ When the factory is quiet (weekend, night time or shut down), can you hear the hiss of compressed air?

2/ When you are not in production is your compressor still running at times?

3/ Is the pressure reading on the receiver in the compressor house higher than the pressure reading at the furthest point of use in the factory?

4/ What pressures do your processes require versus the pressure that is generated by the compressor?

These are easy checks that you can perform yourself. However, when it comes to properly working out the size and scale of the leaks you have in your pipework system it is best to call in the experts with the correct equipment and experience to carry out the task quickly and efficiently.

Air Equipment we use ultrasonic testers to detect even the smallest leaks. The equipment is so sensitive that even a tiny leak (one too small to hear even with your ear close to it) can be detected from many meters away. In fact we have even detected small air leaks from pipework that is boxed in to a wall!

The equipment is able to give a good estimation of the size of the leak so we can calculate for each particular leak how much money is being wasted and what the saving would be if the leak was fixed – giving a great payback estimation.

During our air leak survey process we go round your pipework with an ultrasonic air leak detector. Our engineer identifies and tags each leak, giving it a unique reference, location and scale of leak. In most cases we also photograph the problem area. We then write all this information in a report which we present back to the customer. Normally we also make recommendations as to which leaks we feel should be carried out and the cost to carry out these repairs.

The customer can follow our recommendations or come up with their own, but always knowing how much its going to cost for the repair and how much energy they will save.

We recommend an annual survey with an ongoing programme of repairs, picking off the top 80% of leak volume every year. Payback on this process is typically measured in a few months rather than years. Air leak surveys / repairs are one of the most effective and quickest payback solutions to improving compressed air efficiency.

Call us to arrange a air leak survey for your plant. We normally charge a nominal fee for the initial survey which is credited against repairs you implement.

Excellent Service...

Air Compressor service and repair

Professional support when you need it

Air Equipment can support you and your compressed air system throughout its life. We will monitor your system to ensure it remains reliable, efficient and operating correctly. We will service your compressors, filters and air dryers to schedule, to ensure they continue to operate correctly. We can also help and guide you through changes to your air system as your company changes and grows.

Learn about usSign up to the free newsletter and receive our monthly bulletin.