They have solved any problems we had very promptly....They supplied and serviced our air compressor for last 4 years and have solved any problems we had very promptly. On a recent air receiver purchase which was damaged by the courier they h...

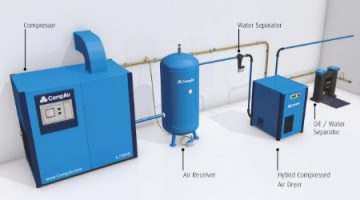

Compressed air dryers are designed to remove water from your compressed air system and pipework. It is important that there isn’t any water in your compressed air since water getting into your process equipment or onto your end product will damage both often with disastrous results.

Whilst the concept is simple, making sure moisture is correctly removed under all climatic conditions, at all times of year, regardless of the amount of air being used can be challenging.

It is also important that the correct range of filters are fitted to your compressed air system, this helps remove additional water but also removes particulates and in some cases oil from the air. Click here to find out more about compressed air filters.

A good understanding of your working environment and the compressed air system is essential to get the correct dryer specified and installed.

To find out more about the different types of compressed air dryer take a look at our short video on dryers

Refrigerant dryers are the most appropriate dryer for most applications. Based on a simple refrigeration pump, they are cheap to operate and maintain. Inside the dryer the compressed air is cooled to about 3’C. The water condenses out and is removed. The, now dry air, is re-heated back to room temperature before leaving the dryer. This re-heating process prevents condensation forming on pipework. outside the dryer

Refrigerant dryers create dry air with a dew point of around 3°C which is perfectly acceptable for most industrial applications. Only if pipework is routed outside (in winter) or through chilled of frozen areas should water re-appear in the compressed air.

Desiccant dryers use a granular absorbent chemical to take moisture out of the air. This chemical process produces air that is much dryer than air that from a refrigerant dryer. Typically desiccant dryers produce air with a dew point of -20°C to -40°C. Desiccant dryers are more costly to buy and operate and require larger compressors to be specified since there is a certain amount of air loss in the regeneration process of the absorbent chemicals. Zero loss dryers are available.

Air with a dew point as low as -20’C or -40’C is only required for specialist applications, such as certain food and pharmaceutical applications. Air of this quality is also sometimes needed for lab work and extreme paint spraying applications.

Desiccant dryers are usually required in applications where very high quality air is required, such as in food, electronics and pharmaceutical industries and sometimes in high quality paint spray applications.

Talk to us if you need more information about desiccant dryers

They have solved any problems we had very promptly....They supplied and serviced our air compressor for last 4 years and have solved any problems we had very promptly. On a recent air receiver purchase which was damaged by the courier they h...

Refrigerant and Desiccant dryers

Air Equipment can support you and your compressed air system throughout its life. We will monitor your system to ensure it remains reliable, efficient and operating correctly. We will service your compressors, filters and air dryers to schedule, to ensure they continue to operate correctly. We can also help and guide you through changes to your air system as your company changes and grows.

Learn about usSign up to the free newsletter and receive our monthly bulletin.