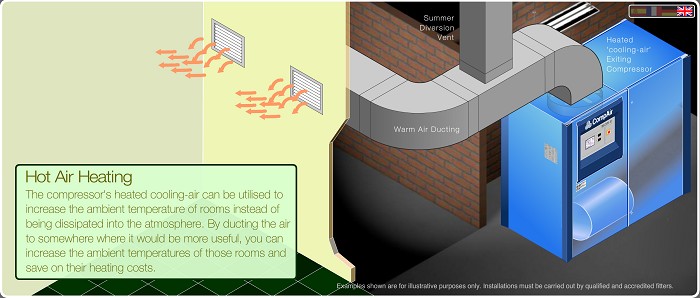

Hot air energy recovery

Your compressor creates a lot of heat as part of the compression process. Typically over 80% of the energy used in the compression process is given off as heat. For a 11KW compressor this means about 9KW of the input energy is given off as heat, this heat is usually released to the atmosphere and wasted. Hot air energy recovery is the process by which this wasted heat is re-used.

The easiest way to re-use this energy is to simply duct the air to somewhere it can be useful. Normally this means ducting the air to a factory or workshop area to act as a space heater. The warm air given off buy the compressor is clean and free from dust or dirt, effectively you get your factory heating for free. Obviously in the summer, when heating is probably the last thing the factory needs, the air should be ducted straight to atmosphere, but this is easily achieved with a simple moveable flap in the ductwork.

Hot air energy recovery using duct work is one of the cheapest and most effective ways of recovering this wasted heat. There are drawbacks however, such as:

1/ The energy will only be recovered through the cold winter months, so is only effective for maybe half the year.

2/ The plant room needs to be located near to the factory / workshop